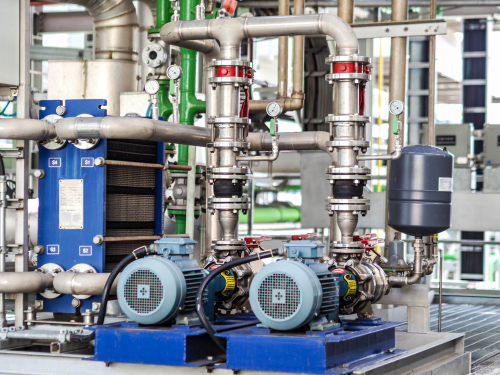

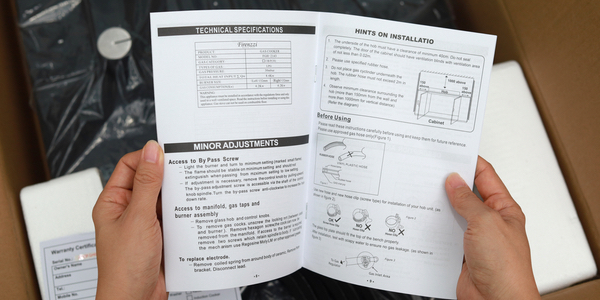

Equipment vendors supply two items – the equipment and associated vendor data

I found that many equipment requisitions had little specific thought for vendor data

Many projects suffer design delays due to this not being sufficiently addressed early enough

Frequently there was more requisition text on data than on specifying the equipment required. Usually in the form of a standard procurement tick list which didn’t take into account the size/capability of the vendor

Time should be taken to first consider and understand what data a typical vendor produces as part of his normal supply. Then:

- What data is actually required for interface design. If it is more than the normal supply, do vendors have the capability to produce it? Can the information be found or produced another way?

- What data is actually needed for the operation and maintenance. If it is more than the normal supply, do vendors have the capability to produce it? Will the operator actually use it (eg during commissioning)?

Note that vendors will probably quote without taking note of the data list – more important to get into the door of the selection process

Secondly in large engineering and procurement organisations there may be vendor data ownership confusion (the specifying engineer and/or buyer) and an unwillingness to edit it in a way suitable for the end-user